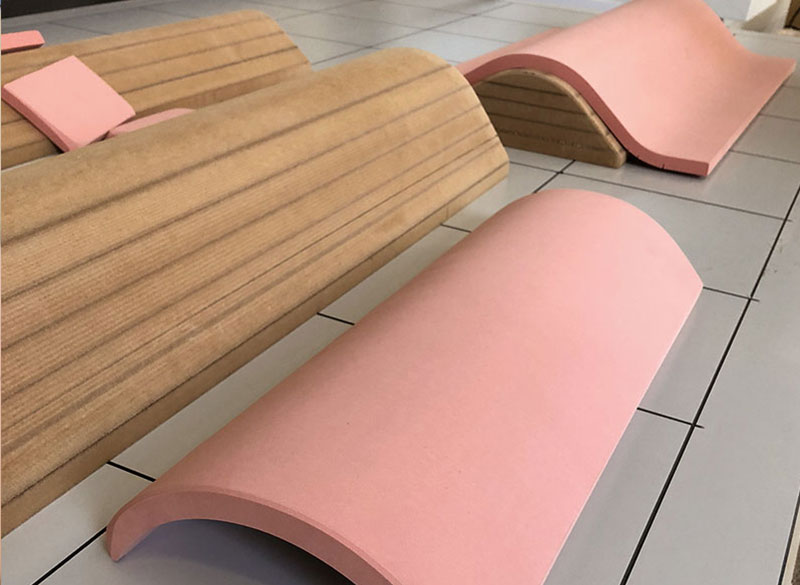

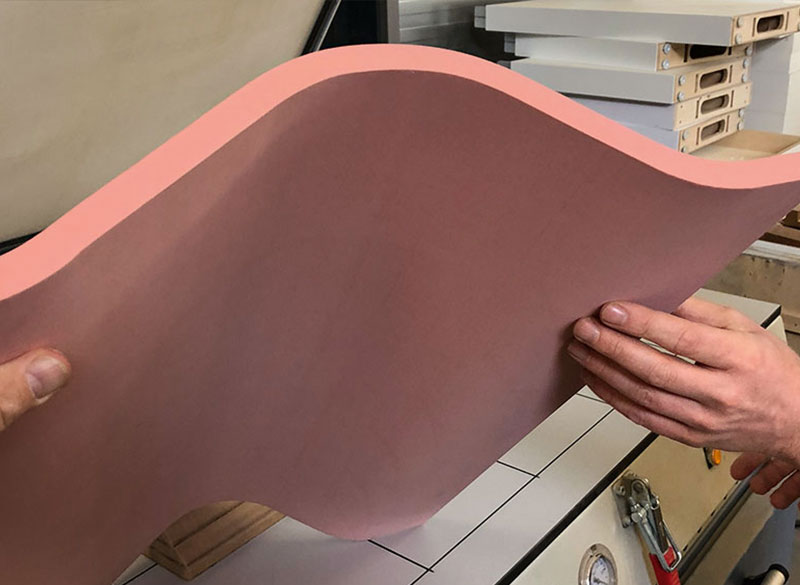

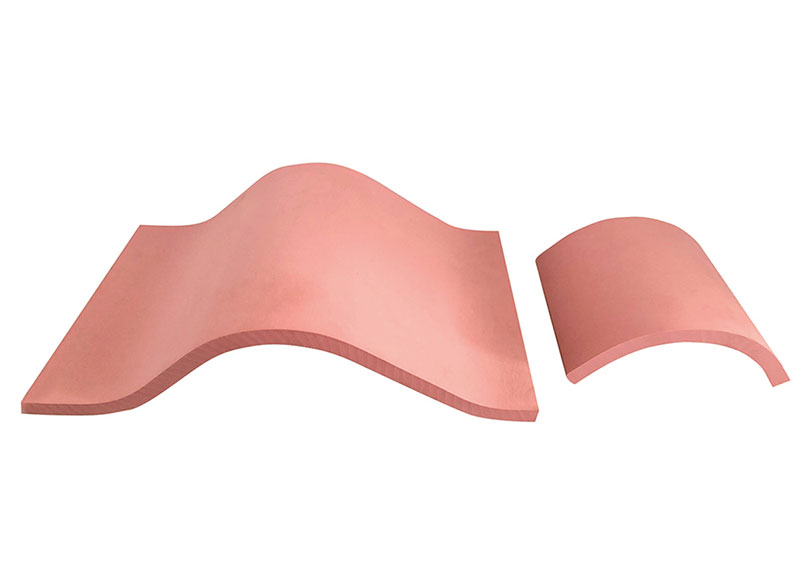

The test was made with a board

of 16 mm thickness on a machine

from the manufacturer GLOBAL.

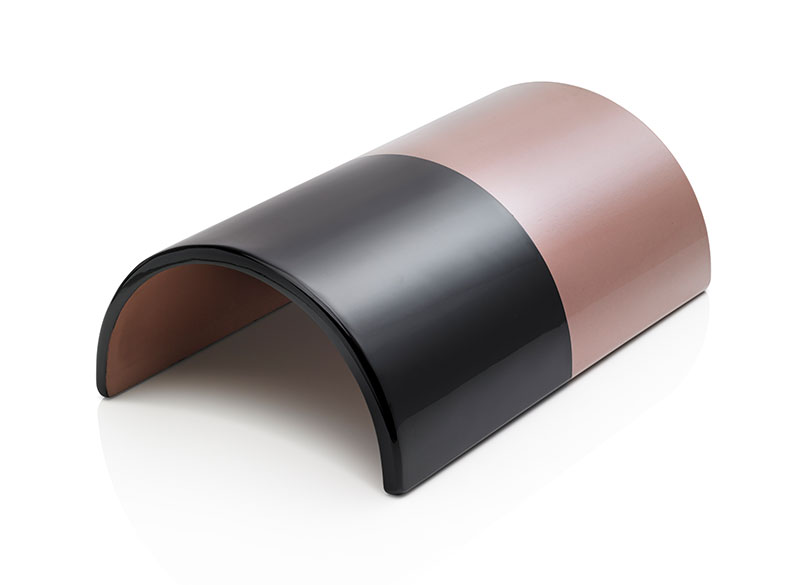

The following process is advised:

- 1. slowly heat the material up to 120-140 °C

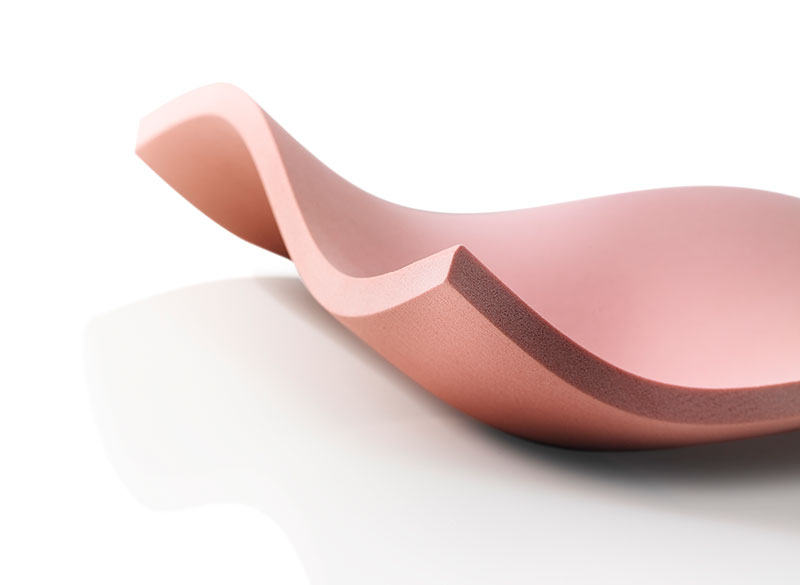

- 2. bend the material over a block with the requested curvature

- 3. the material must be cooled down slowly again

- 4. the material should be stored and transported according to the shape