Cutting / Formatting

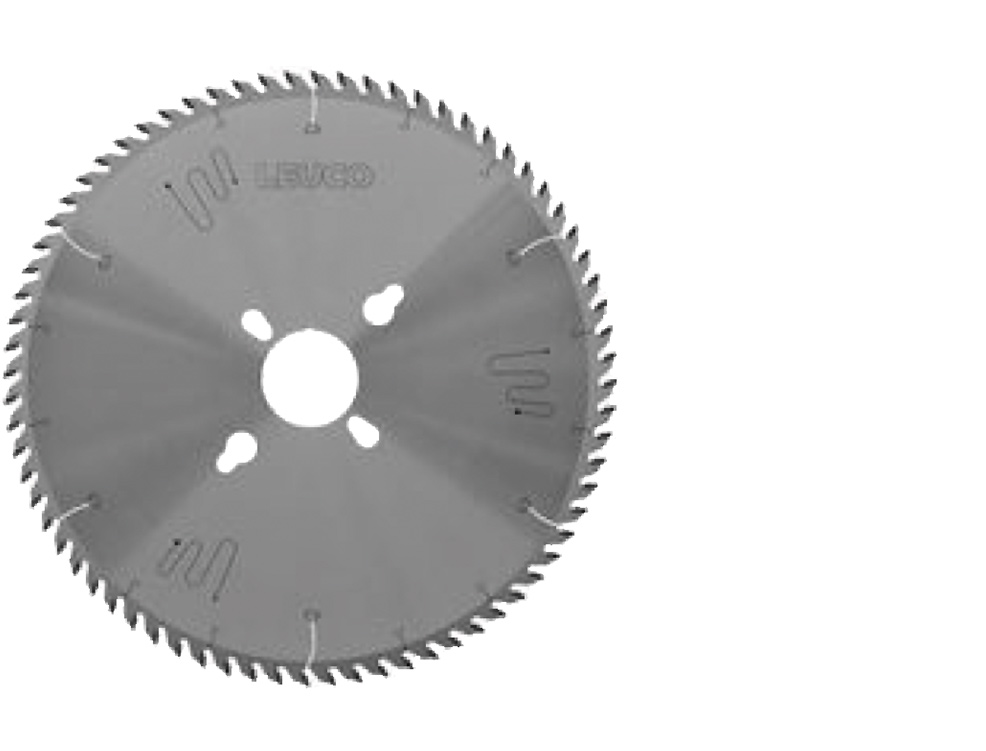

Panel cutting with circular saw blades

Various factors are responsible for good cutting results:

- decorative side face up

- correct saw blade projection

- feed of speed

- tooth profile

- tooth pitch

- rpm

- speed

The recommended cutting speed is 70 - 90 m/sec.

The higher value should be selected in case of polycrystalline diamond tipped circular saw blades. Try to aim for a feed per tooth of 0.06 - 0.07 mm.

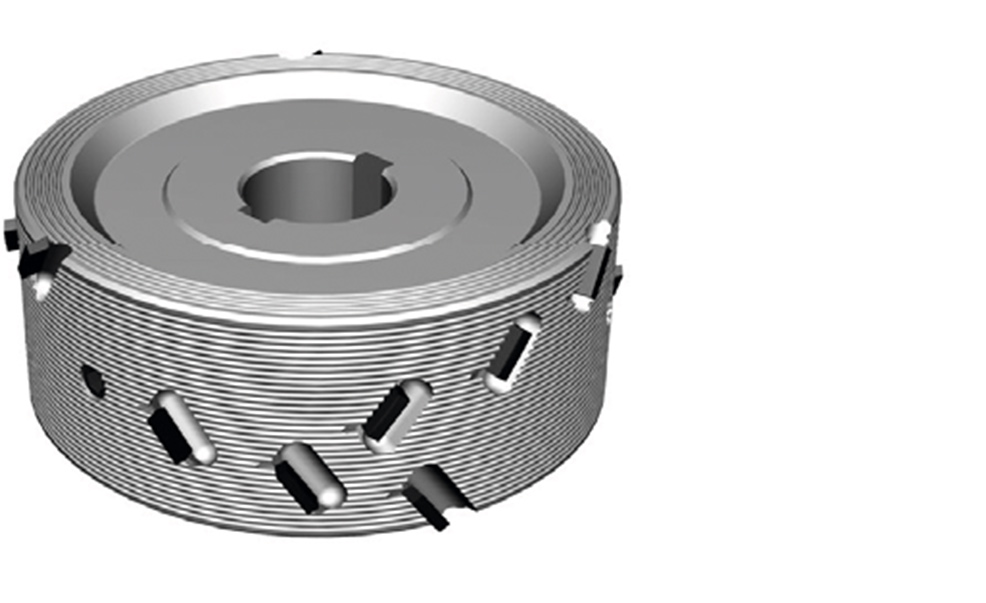

Milling / edge processing

In general, tools with carbide-tipped and diamond-tipped blades should be used for jointing work in the continuous process. For formatting with jointing cutters, very good results can be achieved with tools that have a small shaft angle. For diamond-tipped tools, a shaft angle of 35° and for a cutter head with carbide tipped turnover board knives, a shaft angle of 15° is suitable. The ideal feed per tooth (fz) is between 0.7 - 0.75 mm.

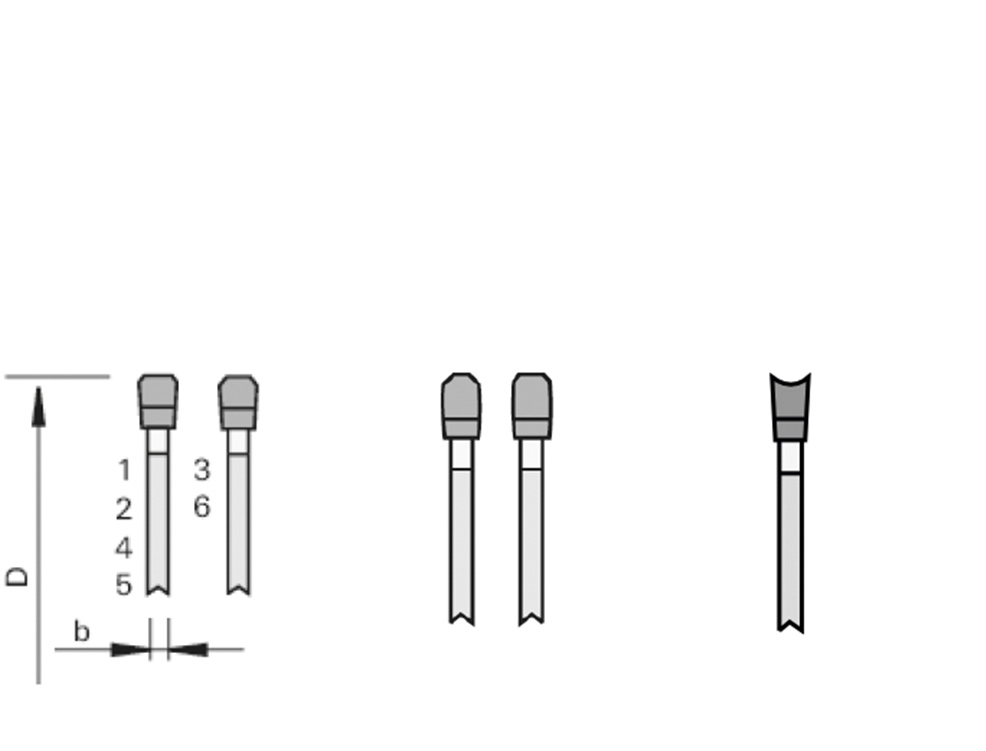

Processing on CNC machines

Separating cuts, jointing cuts, pocket milling, etc. can be performed easily with common shank-type cutters. The right choice depends on the requirements regarding the desired cutting quality. As solid carbide shank type cutters are provided with continuous cutting edges, they are ideal to use. Absolutely smooth cuts can be achieved using solid carbide shank type cutters with continuous cutting edges with spiral and turnover board knives. Also diamond-tipped tools with a small shaft angle work very well.